Welcome to IRSA SANAT KHARAZMI (ISK), a global leader in delivering innovative, reliable, and sustainable water and wastewater treatment solutions. With our in-house engineering, procurement, and state-of-the-art fabrication capabilities, we provide complete systems, modular packages, and EPC (Engineering, Procurement, and Construction) services tailored to meet the unique needs of our clients worldwide, particularly in the Middle East.

Comprehensive Solutions for Water and Wastewater Treatment

At IRSA SANAT KHARAZMI (ISK), we design, fabricate, and deliver end-to-end water and wastewater treatment systems that ensure efficiency, compliance, and environmental sustainability. Our solutions cater to municipal, industrial, and commercial applications, addressing challenges such as water scarcity, regulatory requirements, and operational efficiency.

Our Offerings

- Complete Treatment Systems: Fully integrated solutions for potable water, industrial process water, and wastewater treatment, including pretreatment, filtration, disinfection, and sludge management.

- Modular Equipment & Packages: Pre-engineered, skid-mounted systems for rapid deployment and scalability, ideal for remote sites, temporary facilities, or phased projects.

- Custom Fabrication: Leveraging our advanced fabrication facility, we build bespoke treatment packages tailored to project specifications, ensuring quality and performance.

- EPC Services: Turnkey project execution, from conceptual design and procurement to construction and commissioning, with a focus on cost-efficiency and timely delivery.

Why Choose IRSA SANAT KHARAZMI (ISK)?

In-House Expertise

Our dedicated Engineering Department combines cutting-edge design tools with decades of experience to deliver solutions that meet stringent technical and environmental standards. From feasibility studies to detailed engineering, we ensure precision at every stage.

Global Procurement Excellence

Our Procurement Department sources high-quality components from trusted global suppliers, optimizing costs without compromising reliability. We streamline supply chains to support projects of any scale, anywhere in the world.

Advanced Fabrication Capabilities

Our state-of-the-art factory specializes in fabricating modular treatment packages, pressure vessels, and structural components. With rigorous quality control, we ensure durability and compliance with international standards (e.g., ASME, ISO, AWWA).

Proven EPC Track Record

With extensive experience in EPC projects across the Middle East and beyond, we deliver complex water and wastewater infrastructure projects on time and within budget. Our integrated approach minimizes risks and maximizes value for our clients.

Middle East Focus

We understand the unique challenges of the Middle East, including water scarcity, high salinity, and extreme climates. Our solutions are designed to perform in these conditions, supporting industries like oil and gas, petrochemicals, municipalities, and more.

Our Product Portfolio

1. Pretreatment

Pretreatment removes large solids, grit, and oils to protect downstream processes.

- Screening & Grit Removal: Bar screens and grit chambers eliminate debris and sediments.

- API Separators: Gravity-based oil-water separation for industrial effluents, compliant with API standards.

- Corrugated Plate Interceptors (CPI): Compact, high-efficiency oil and grease removal for petrochemical and refinery wastewater.

- Dissolved Air Flotation (DAF): Microbubble technology for removing suspended solids, oils, and grease with high clarity output.

2. Primary Treatment

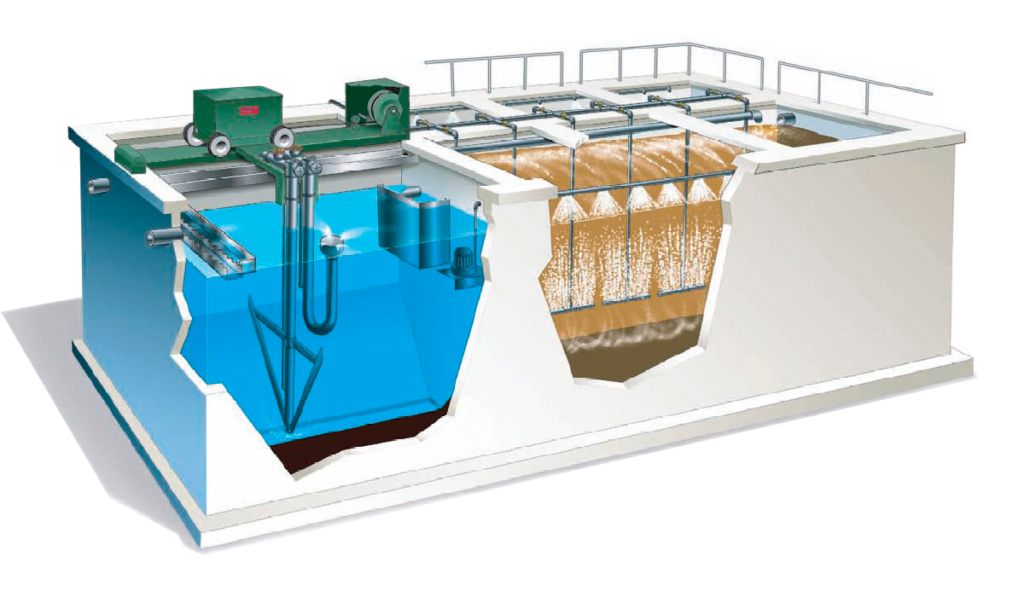

Primary treatment reduces settleable solids and organic loads.

- Clarifiers: Sedimentation tanks for efficient solids settling, designed for high throughput and minimal footprint.

- Chemical Feed Systems: Precise dosing of coagulants and flocculants to enhance solids removal and optimize downstream processes.

3. Secondary Treatment

Secondary treatment biologically degrades organic matter to meet discharge standards.

- Integrated Fixed-Film Activated Sludge (IFAS): Combines suspended and attached growth for enhanced treatment capacity and resilience.

- Moving Bed Biofilm Reactor (MBBR): Compact, modular systems with biofilm carriers for robust organic and nitrogen removal.

- Membrane Bioreactors (MBR): Advanced membrane filtration paired with biological treatment for superior effluent quality and water reuse.

4. Sludge Treatment

Sludge treatment minimizes waste and enables resource recovery.

- Thickening & Dewatering: Belt presses, centrifuges, and screw presses reduce sludge volume.

- Digestion: Aerobic or anaerobic processes stabilize sludge and produce biogas for energy recovery.

- Drying: Thermal drying systems for safe disposal or reuse as fertilizer.

5. Tertiary Treatment

Tertiary treatment polishes effluent for reuse or sensitive discharge.

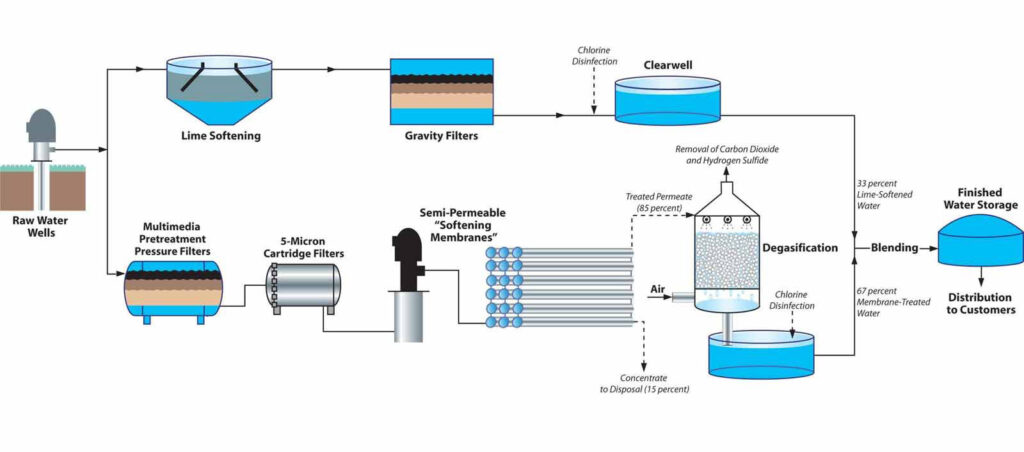

- Membrane Processes: Ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO) for high-purity water.

- Ion Exchange: Resin-based systems for removing specific contaminants like heavy metals or hardness.

- Treated Water Disinfection: UV, ozone, or chlorination to eliminate pathogens, ensuring safe reuse or discharge.

6. Odor Treatment

Odor control is seamlessly integrated into our systems to ensure environmental compliance and community acceptance.

- Chemical Scrubbers: Neutralize odorous gases like hydrogen sulfide (H2S) with high efficiency.

- Biofilters: Eco-friendly biological degradation of volatile organic compounds (VOCs).

- Activated Carbon Systems: Adsorption-based solutions for low-maintenance odor removal.

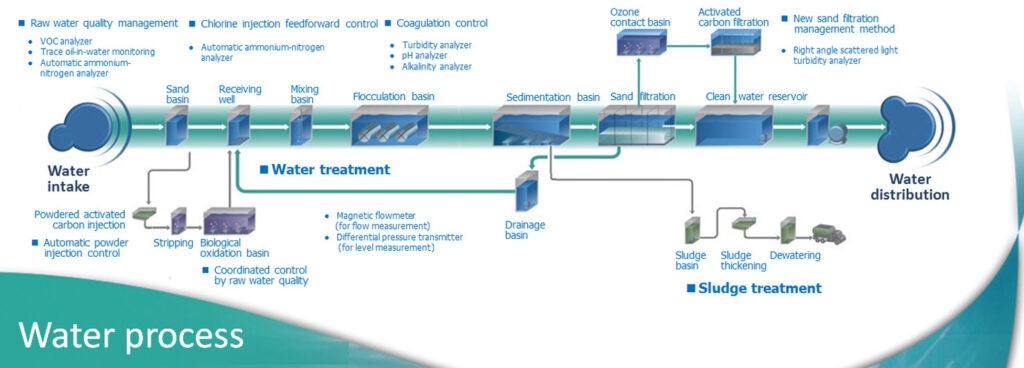

7. Raw Water Treatment

For raw water applications, we provide tailored pretreatment and purification.

- Filtration Systems: Sand, multimedia, or cartridge filters for suspended solids removal.

- Chemical Feed: Coagulation and pH adjustment for optimal water quality.

- Disinfection: Pre-treatment disinfection to ensure safe processing.

Our Technology Portfolio

We leverage industry-leading technologies to deliver modular packages and complete systems, fabricated in our state-of-the-art facility and supported by global procurement expertise.

- API & CPI Units: Robust oil-water separation for heavy industrial wastewater.

- Clarifiers & DAF Systems: High-efficiency solids and oil removal for primary treatment.

- IFAS & MBBR Systems: Flexible, scalable biological treatment for organic and nitrogen removal.

- Membrane Processes (MBR, UF, RO): Advanced filtration for water reuse and compliance.

- Chemical Feed Systems: Automated dosing for process optimization.

- Ion Exchange Units: Targeted contaminant removal for industrial applications.

- Disinfection Systems: UV, ozone, and chlorination for raw and treated water safety.

- Reverse Osmosis (RO) Systems: High-efficiency desalination and purification for potable and industrial water.

- Ultrafiltration (UF) & Microfiltration (MF): Advanced membrane technologies for water clarification and reuse.

- Ion Exchange Systems: Softening and demineralization for boiler feedwater and process applications.

- Disinfection Systems: UV, ozone, and chlorination solutions for safe, pathogen-free water.

2. Wastewater Treatment Systems

- Membrane Bioreactors (MBR): Compact, high-performance systems for wastewater reuse and discharge compliance.

- Sequencing Batch Reactors (SBR): Flexible, cost-effective solutions for municipal and industrial wastewater.

- Sludge Treatment: Dewatering, thickening, and drying systems to minimize waste and enable resource recovery.

- Odor Control Systems: Biofilters and chemical scrubbers for environmental compliance.

3. Modular Treatment Packages

- Containerized Systems: Plug-and-play solutions for remote or temporary applications, including RO, MBR, and filtration units.

- Skid-Mounted Units: Pre-assembled packages for rapid installation and minimal site work.

- Mobile Water Treatment: Trailer-mounted systems for emergency response or short-term needs.

4. Ancillary Equipment

- Chemical Dosing Systems: Precise dosing for coagulation, flocculation, and pH control.

- Pumping Stations: High-efficiency pumps for water transfer and circulation.

- Control Systems: PLC-based automation for real-time monitoring and operational efficiency.

Applications

Our solutions serve a wide range of industries and sectors, including:

- Municipalities: Drinking water treatment, sewage treatment, and water reuse.

- Oil & Gas: Produced water treatment, desalination, and wastewater management.

- Petrochemicals: Process water and effluent treatment for regulatory compliance.

- Power Generation: Boiler feedwater and cooling tower water treatment.

- Mining: Water recovery and tailings management.

- Food & Beverage: High-purity water for production and wastewater treatment.

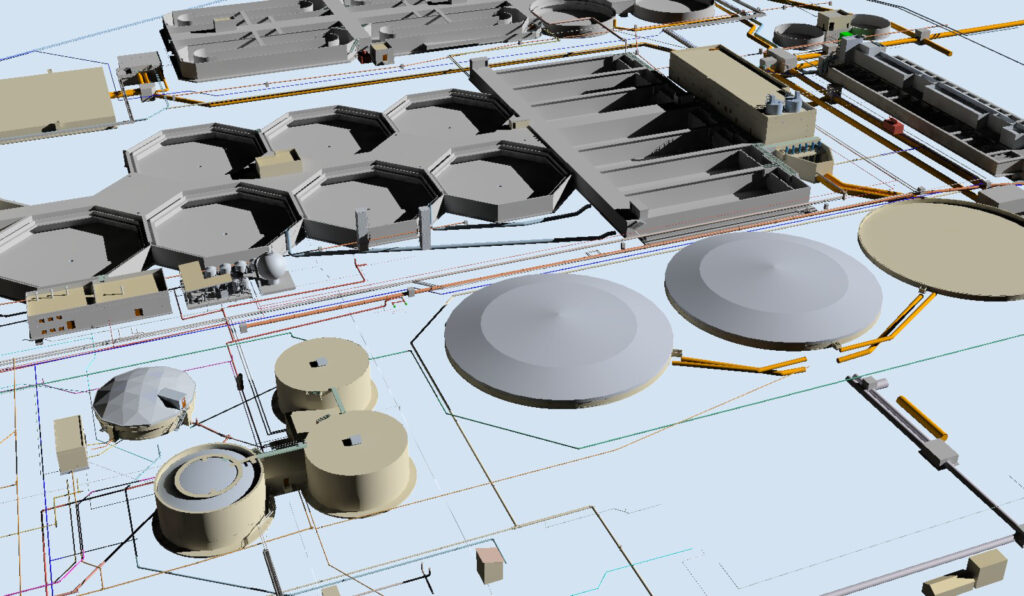

EPC Projects: Delivering Turnkey Excellence

As a trusted EPC contractor, we manage every aspect of your water and wastewater treatment project:

- Engineering: Process design, P&ID development, and 3D modeling.

- Procurement: Global sourcing of equipment, materials, and instrumentation.

- Construction: Site preparation, installation, and system integration.

- Commissioning: Performance testing and operator training for seamless handover.

Our EPC projects are executed with a commitment to safety, sustainability, and client satisfaction, ensuring long-term operational success.

Sustainability Commitment

At IRSA SANAT KHARAZMI (ISK), we prioritize environmental stewardship. Our systems are designed to:

- Reduce energy consumption through advanced technologies.

- Maximize water reuse and resource recovery.

- Minimize waste and emissions for a cleaner planet.

Global Reach, Local Expertise

With a strong presence in the Middle East, we combine global best practices with local knowledge to deliver solutions that meet regional needs. Our project portfolio spans Saudi Arabia, UAE, Qatar, Oman, and beyond, with successful implementations in urban centers and remote locations alike.